All Products

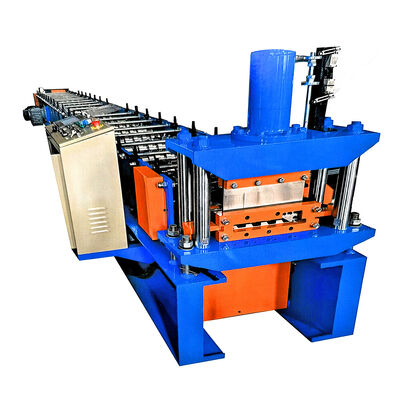

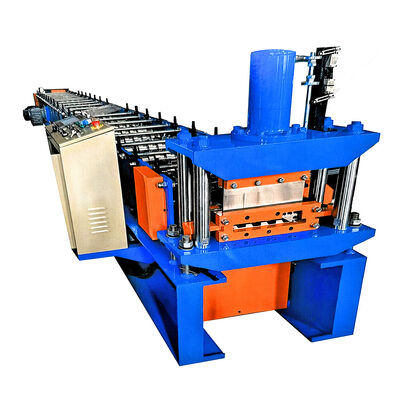

Hydraulic Cutting Roll Forming Machine with 6-8m/min Speed and PLC Control System for Roof Panels

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Material | Steel Coil, Galvanized, PPGI, Aluminum | Cutting Mode | Hydraulic |

|---|---|---|---|

| Speed | 6-8m/min(including Punching And Cutting Time) | HS Code | 84552210 |

| Warranty | 12 Months | Payment | T/T |

| Highlight | Hydraulic Cutting Roll Forming Machine,6-8m/min Speed Roof Panel Roll Former,PLC Control System Metal Roll Forming Machine |

||

Product Description

Seam Lock Roll Forming Machine for Corrugated Roof Sheets

This advanced corrugated roll forming machine specializes in producing high-quality corrugated metal sheets for roofing, wall cladding, and agricultural/industrial facility coverings. Engineered for exceptional strength and durability, these roofing sheets meet the demanding requirements of various construction and engineering applications.

Floor Deck Corrugated Roof Roll Forming Machine

Related Roll Forming Solutions

C/Z/U Purlin Roll Forming Machine - The C-shaped purlin formed by our Roll Forming Machine for C Purlin offers excellent anti-bending properties and easy installation. Built with cast-iron structure for enhanced machine strength.

Premium Roof Sheet Forming Technology

In today's competitive construction industry, high-quality roofing materials are essential for durable, weather-resistant buildings. YingYee Machinery's Roof Sheet Forming Machine delivers precision, efficiency, and reliability in producing top-tier roofing sheets for corrugated, trapezoidal, and glazed tile profiles.

Key Machine Features

- Fully automated operation reduces labor costs and minimizes human error

- PLC control system enables quick adjustments to different profiles and thicknesses

- High-strength forming rollers ensure uniform sheet shapes

- Hydraulic cutting system delivers clean, precise cuts without deformation

- Energy-efficient design reduces power consumption for cost-effective production

- Meets international quality standards for long-lasting performance

Production Workflow

Decoiler → Feeding Guide → Main Roll Forming Machine → PLC Control System → Hydraulic Punching → Hydraulic Cutting → Output Table

Machine Variants

| Single Layer Roll Forming Making Machine | Corrugated Roof Sheet Roll Forming Machinery | Double Layer Roll Forming Machine |

| Floor Deck Roll Forming Machine | Seam Lock Roll Forming Machine |

Finished Products

Quality Certification

Why Choose YingYee Machinery?

Frequently Asked Questions

Are you a factory or trading company?

We are manufacturers and also do export trade.

Where is your factory located?

Weifang Wilda Machinery CO.,Ltd is located in Shandong province of China, with 19 years of experience in metal raw material and products manufacturing.

Can I get some samples?

Yes, we are pleased to provide you with samples of our products.

How about your quality?

We seriously control quality from raw material to finished products. BV, ISO certificates and SGS tests can be provided to ensure qualified goods.

Price advantage?

Our price is competitive, and as manufacturers, you get direct pricing benefits.

Could you design and produce custom solutions?

Yes, we have professional engineers who can design and produce special products according to customer requirements, including special sizes, controls, or OEM services.

Do you look for agents?

Yes, we're looking for agents worldwide. Please contact us for further discussion.

Recommended Products